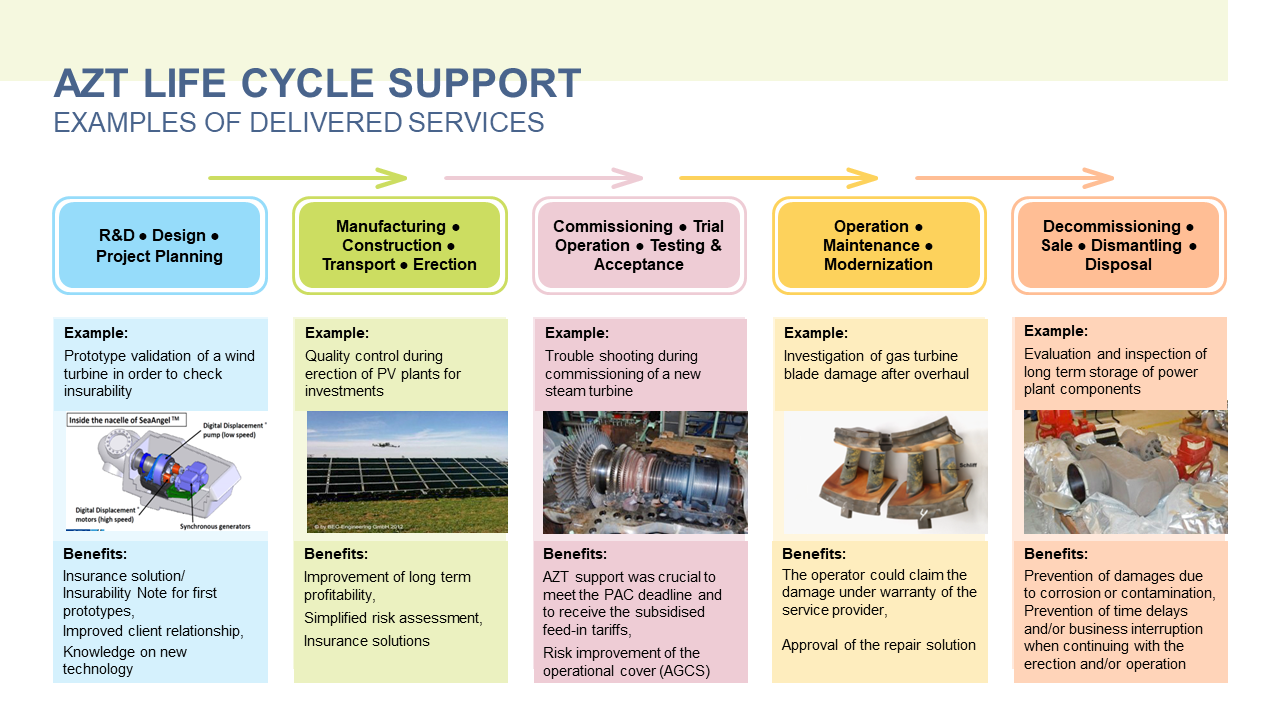

AZT Life Cycle Support

- AZT provides technical support for clients, risk engineers and loss adjusters, worldwide

- AZT services include in-depth failure analysis, development of failure prevention measures and analysis of construction and operational risks of industrial plants and machinery.

- AZT services are provided to clients on a fee basis via Allianz Risk Consulting GmbH, a division of Allianz Global Corporate & Specialty (AGCS).

YOUR BENEFITS

- Recognize and manage critical technical risks in all project phases

- Manage technical issues efficiently

- Optimize operations, minimize business interruption

- Make decisions based on assessments by independent and recognized experts

AZT SERVICES

KNOW MORE. ACHIEVE MORE.

MORE THAN 80 YEARS OF EXPERIENCE – AT YOUR SERVICE.

AZT is the Allianz Group’s center of competence for objective and interdisciplinary assessment and consulting for complex risks and damages in industry and power plants. Our expertise is built on more than 80 years of analysis and research. Read more:

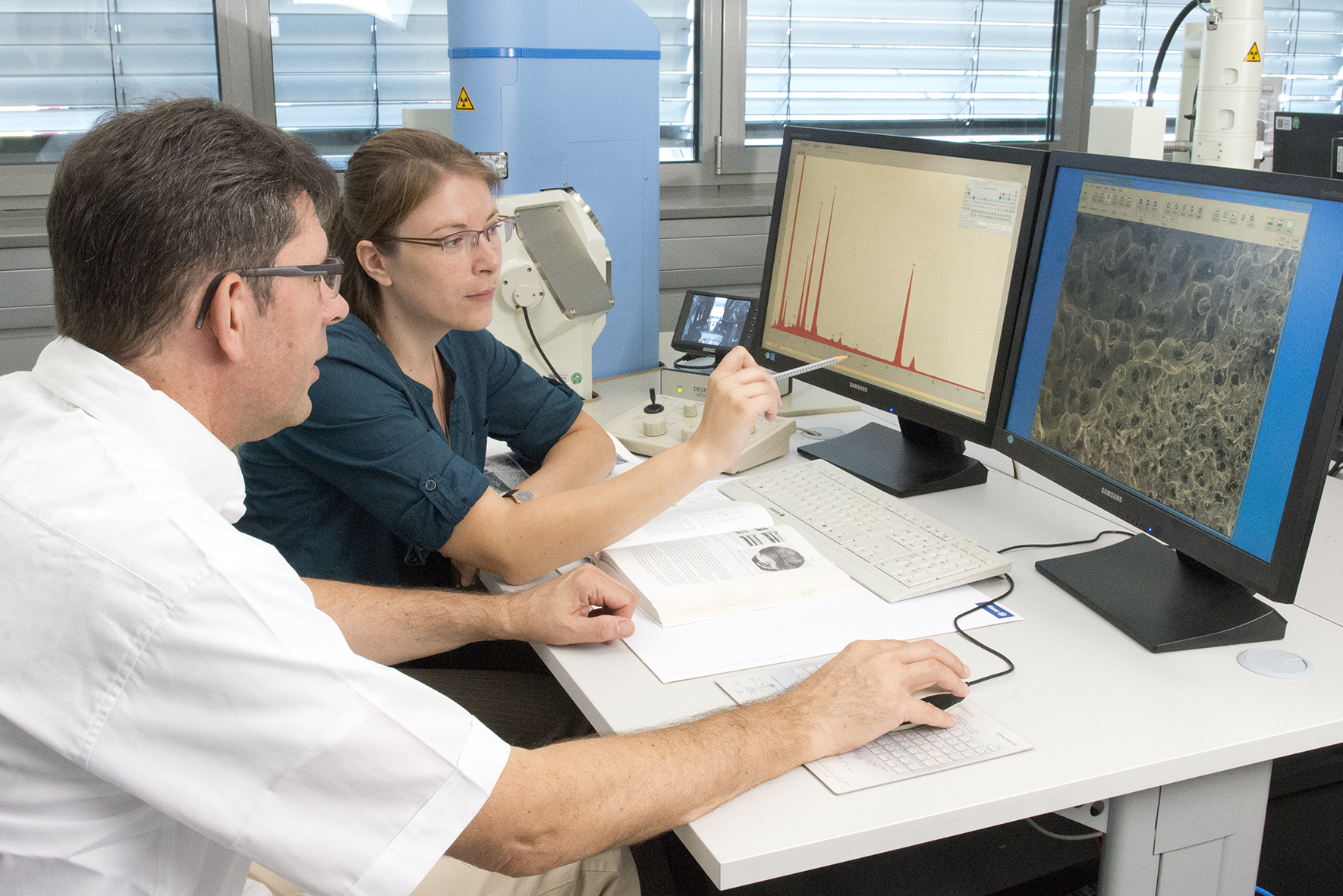

LABORATORY SERVICES ANALYSIS – EXAMINATION – TESTS

The causes of damage to machines or technical systems often lie in details invisible to the eye. At the Cooperation Laboratory of the Allianz Center for Technology (AZT) and the “Gesellschaft für Werkstoffprüfung” (GWP), experts assess damages and analyze the quality of materials and constructions. Read more:

TECHNICAL PRE- AND POST-LOSS SUPPORT FOR PHOTOVOLTAIC PLANTS

SUPPORT THROUGH ALL PROJECT PHASES WITH CUSTOMISED SERVICE

Photovoltaic (PV) power plants are complex systems with a large number of technical components. Their reliability and interaction over decades at exposed locations is key to safe and economic operation and successful investments. However, our experience shows that many PV plants do not operate profitably or do not achieve maximum yields – e.g. due to planning, installation or operational errors. AZT provides world wide support with a high level of expertise throughout all phases of PV projects, in order to prevent damage and avoid yield loss, thus exploiting the full potential of PV power plants. Read more:

WIND TURBINES – ROOT CAUSE ANALYSIS AND CONSULTING SERVICES

The growing demand for renewable energy sources has seen a significant increase in the use of wind energy. The rapid development in the size of these plants has generated a variety of challenges and some major technical problems. Read more:

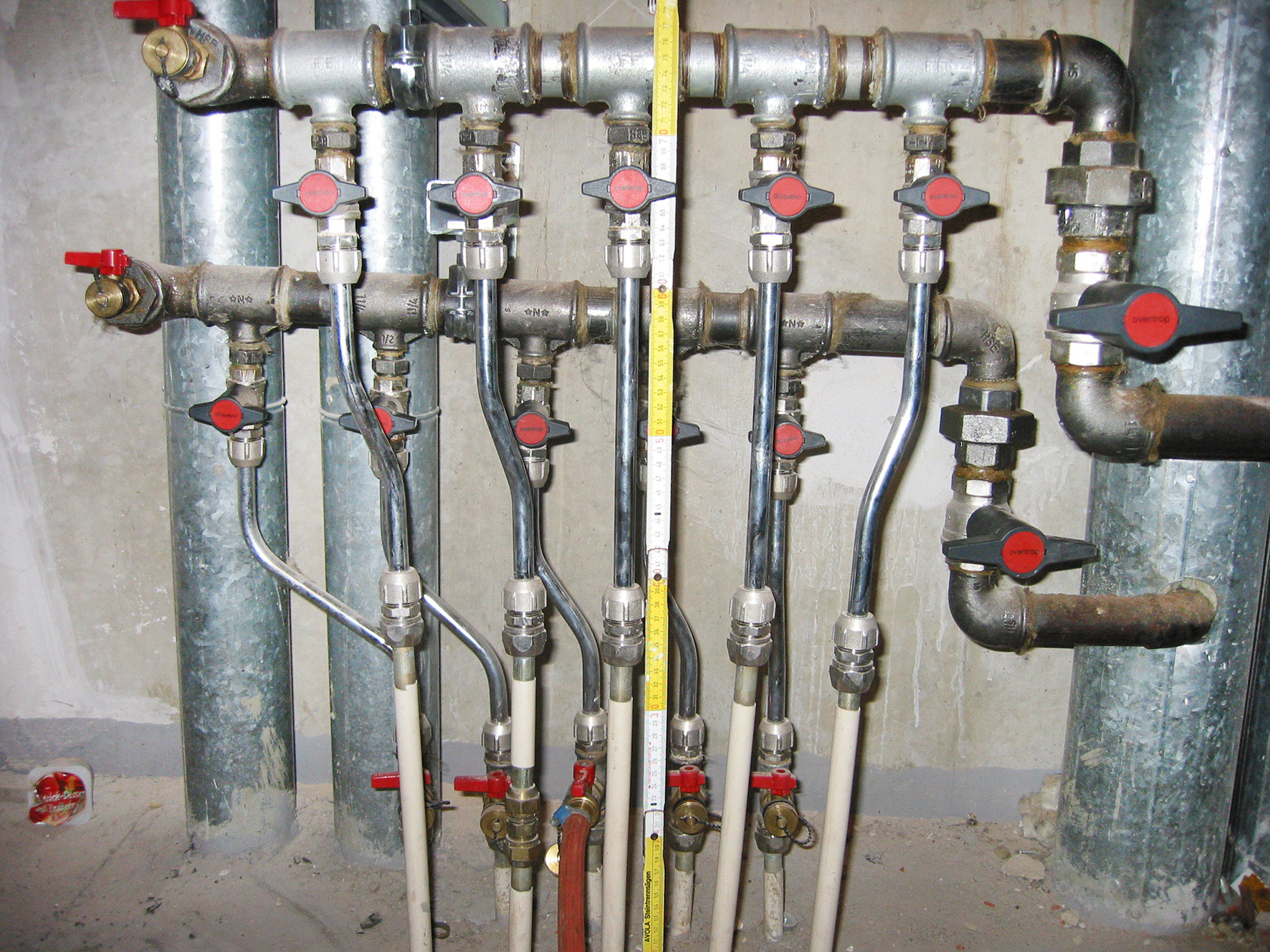

WATER DAMAGE IN BUILDINGS CAUSED BY LEAKING PIPES

Water damage in buildings is often caused by small leaks in water pipes. Often pinholes are responsible for high cost secondary damages to buildings and equipment. If it happens the long delivery times of replacement system components may result in substantial costs caused by delays during construction and business interruption. Read more:

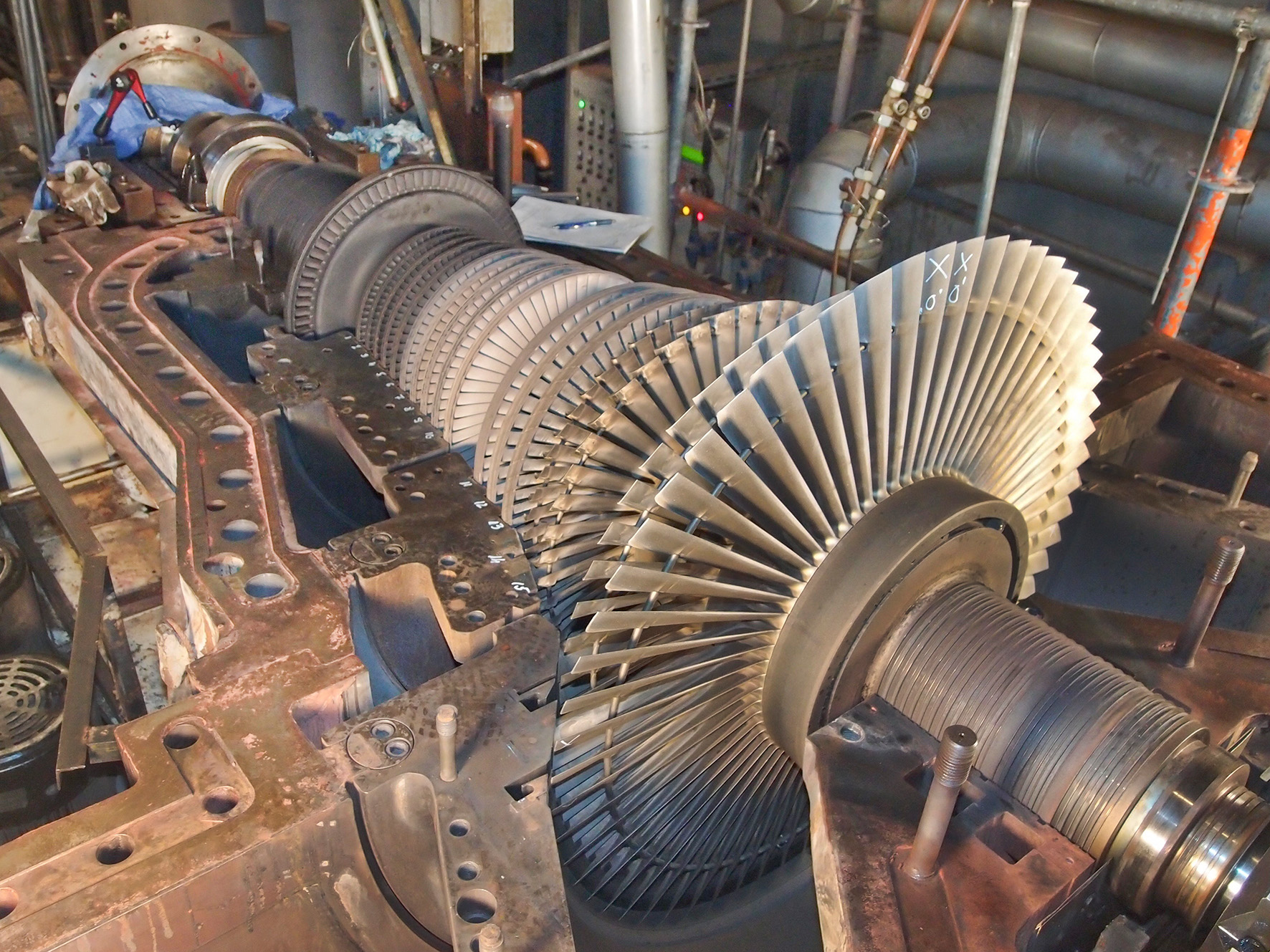

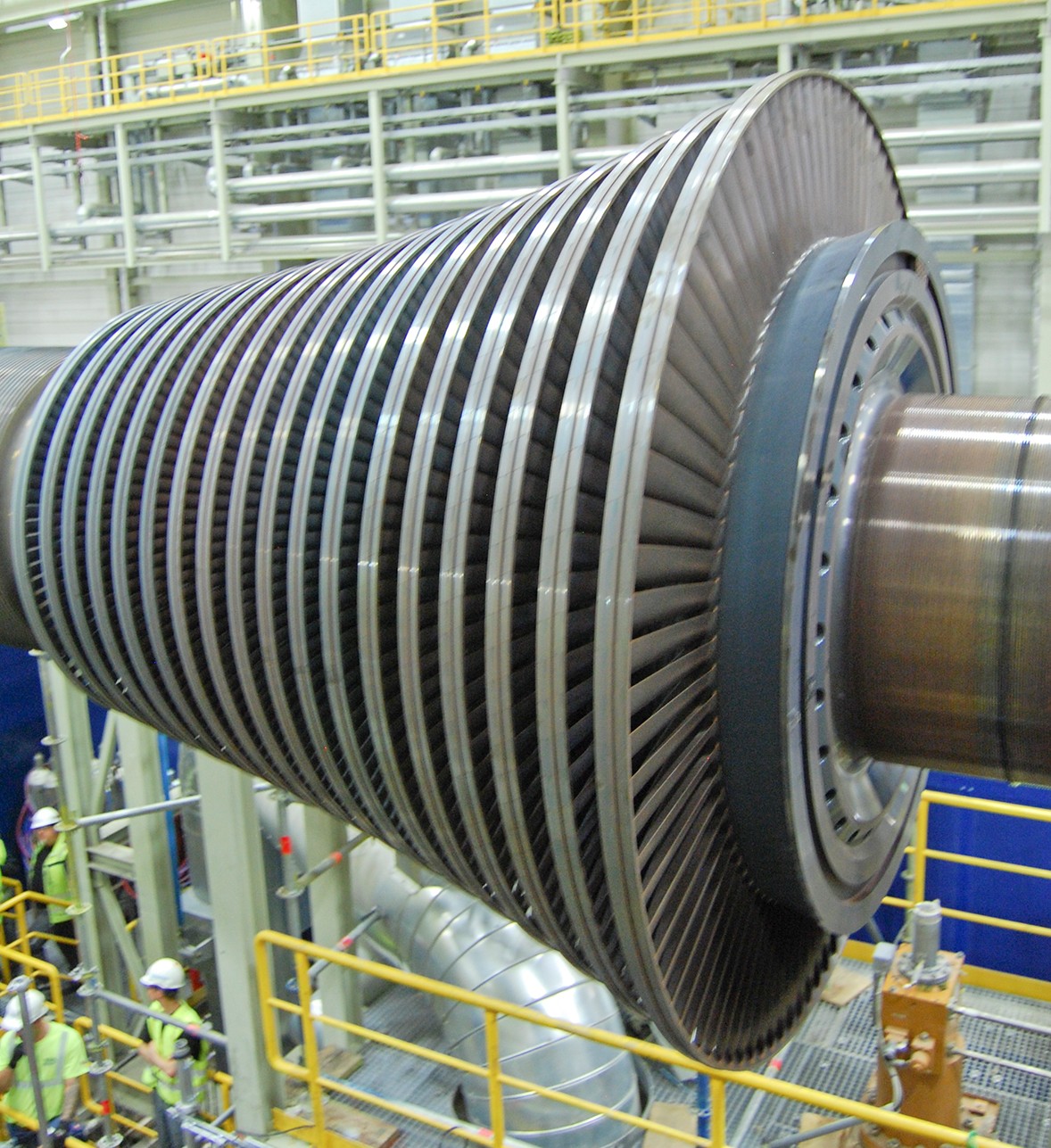

INDEPENDENT SERVICES FOR STEAM TURBINE ACCEPTANCE TESTS

After commissioning a steam turbine, thermal acceptance tests are conducted to prove that the steam turbine fulfills the contractually agreed performance. This often covers heat rate and maximum power output for various load points. Read more:

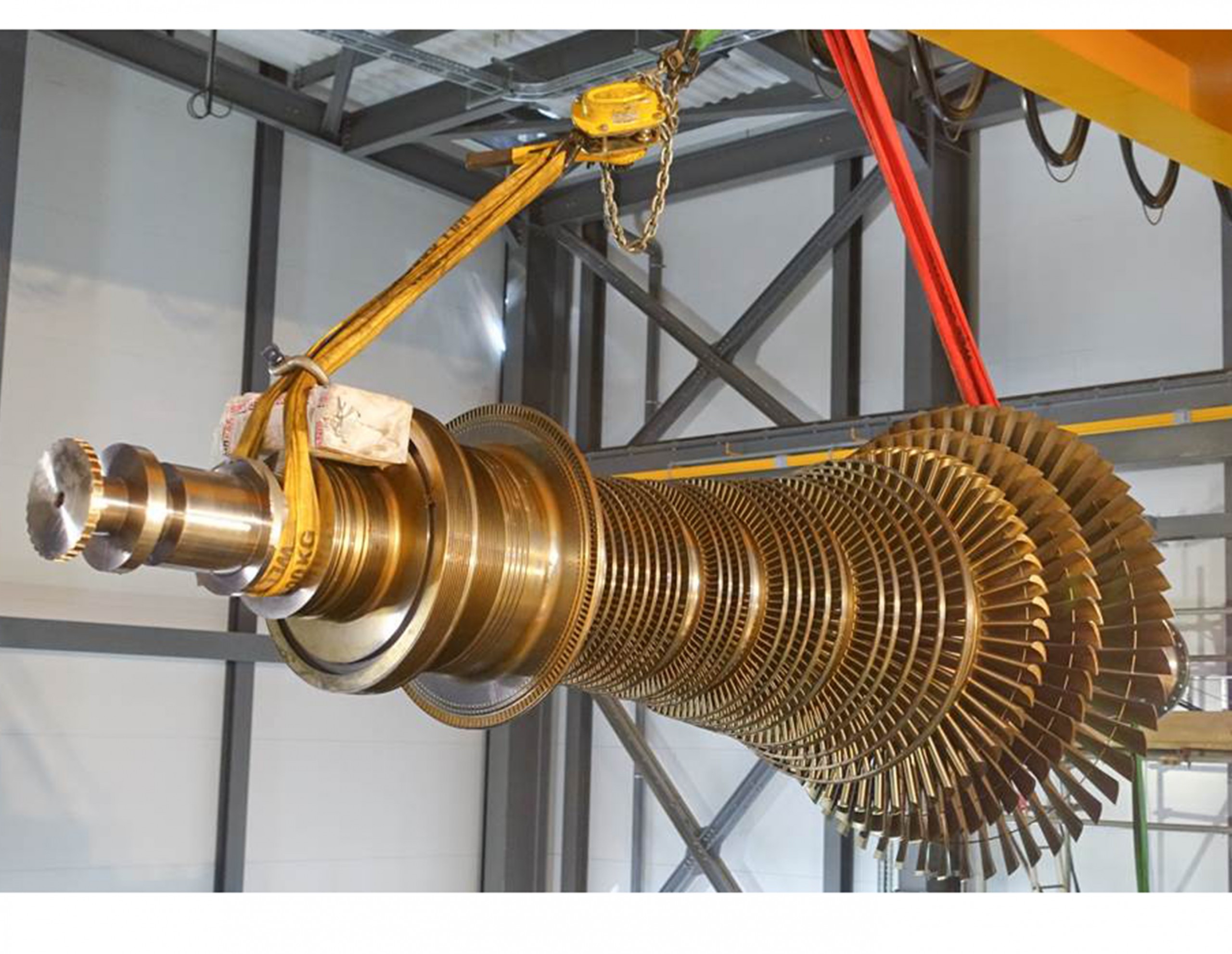

ROTOR BALANCING – CONSULTANCY AND WITNESSING OF HIGH SPEED BALANCING

Correct balancing of rotating components is essential to ensure reliable and safe machine operation. Rotor out of balance can result in large centrifugal forces. This can cause high machinery vibration, which can limit usage and life. Especially for high value machinery, such as turbines and generators, balancing quality is essential, when newly installed, overhauled as well as for the whole period of operation. Read more:

MACHINERY DIAGNOSTICS AND VIBRATION ANALYSIS SERVICES

Safe and reliable turbo machinery operation requires adequate vibration levels. To evaluate vibration and its behaviour specific knowledge is needed. For example, at what point do vibrations start to cause damage and where exactly do the different components of vibration come from? These are questions that Allianz Center for Technology (Allianz Zentrum für Technik – AZT) has been asking for more than four decades to assist its clients in analyzing and solving problems caused by vibration. Read more:

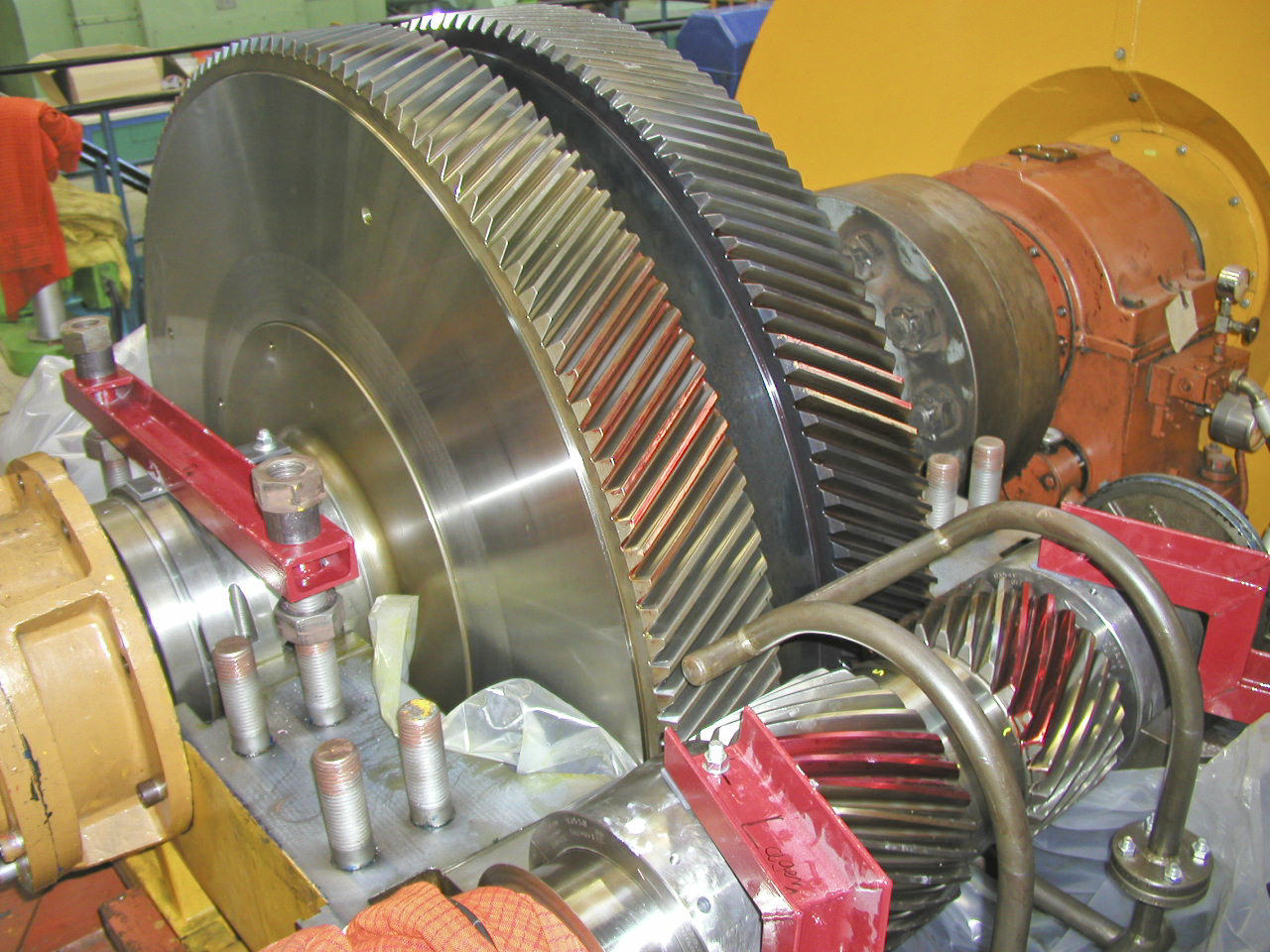

GEARBOX CONSULTING SERVICES

In drivetrains, a gearbox is needed to transform the power input from the drive unit (e.g. turbine or electric motor) according to the requirements (torque/speed) of the working machine (e.g. generator). In most cases the gearbox is not the high-value component in this setup. Nevertheless, a gearbox failure cuts off the connection between the drive unit and the working machine, potentially resulting in long standstill periods because of long lead-times for gears. Read more:

WATER TREATMENT AND CONDITIONING OF WATER/STEAM CYCLE

Insufficient water steam quality can lead to formation of deposits on steam turbine blading, or even more severely, to corrosion of components in the water steam cycle. Adequate conditioning of the feed water in the steam generator, as well as continuous monitoring, is essential to guarantee a good quality water steam cycle. Read more:

LUBRICANTS – CONSULTING SERVICES FOR TURBINES, GEARS, GAS/DIESEL ENGINES

Oil quality deteriorates due to thermal, chemical and physical influences during operation which can lead to overheating of bearings in steam and gas turbines or to corrosion in gas motor bearings.

If the oil and bearings are not changed in time, severe damage to high-cost parts such as turbine rotors, crank shafts and gears can occur. In case of thermal oil boilers, continuous carbonization of the oil can lead to a complete stoppage. Read more:

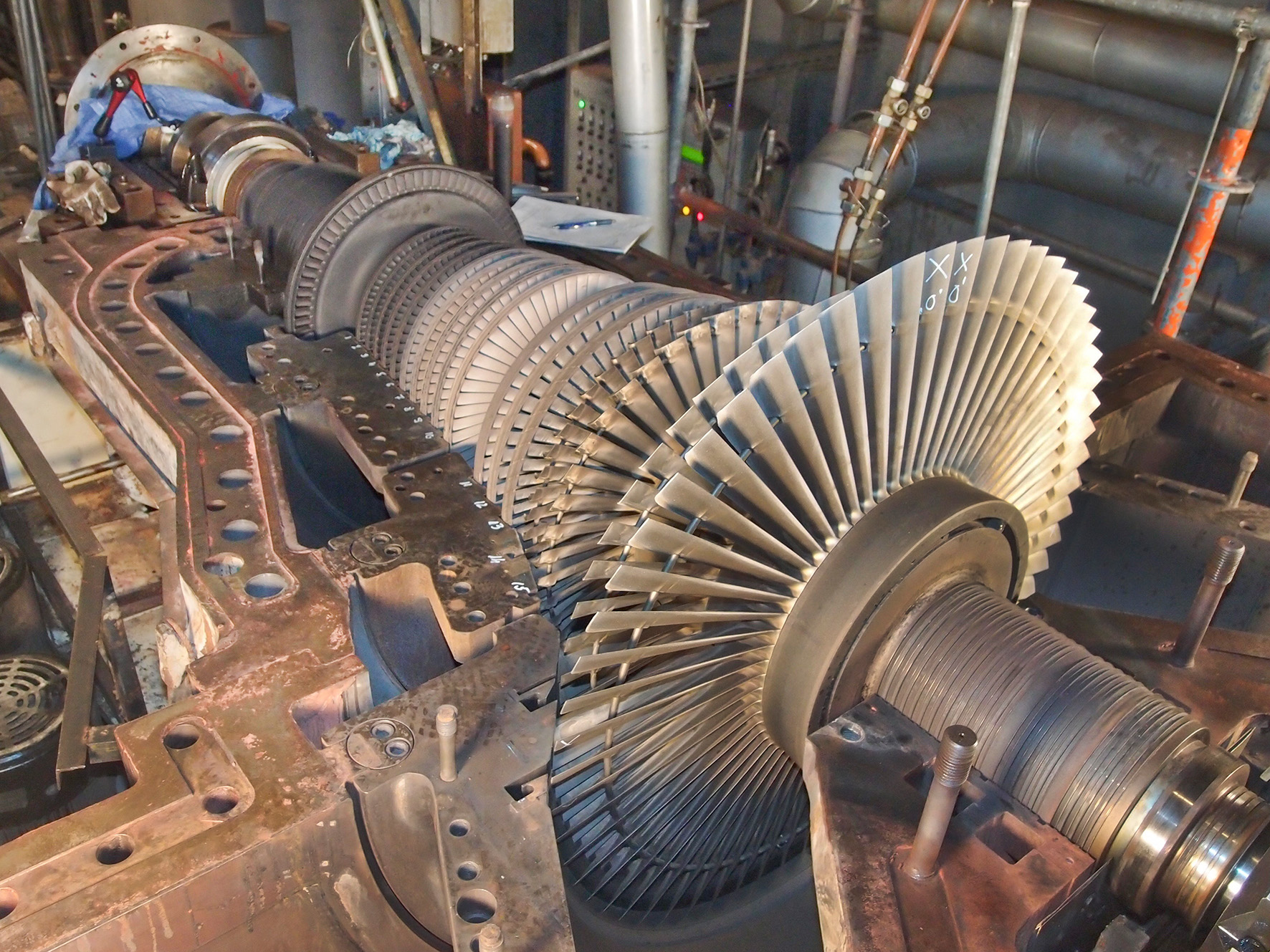

STEAM TURBO SET OVERHAUL FREQUENCY

Rising costs cause increasing pressure on the operators of industrial turbo sets to extend the time between major overhauls. This is linked to an increase in the operational risk for steam turbines, gearboxes and generators. Read more:

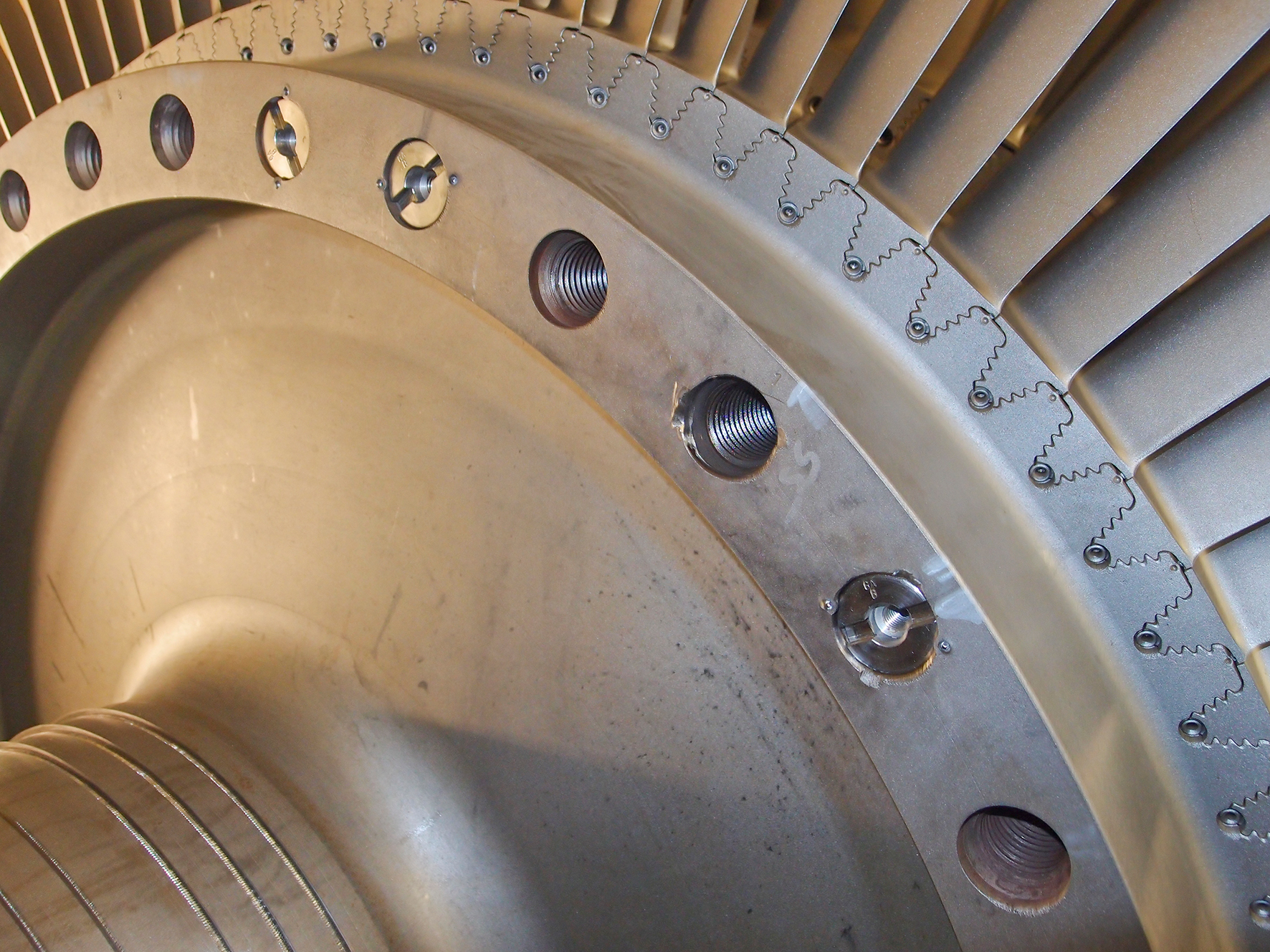

OVERHAUL AND REPAIR OF GAS TURBINE COMPONENTS

The decision whether to replace or repair gas turbine (GT) components is often not an easy one. AZT with its significant experience in detailed inspection of high value parts offers an independent, professional analysis on reparability. This includes visual inspection, non-destructive testing (NDT), mechanical testing and metallurgical investigation checking the state of the material – helping plant operators to come to the best conclusion for their business. Read more:

STORAGE AND PRESERVATION OF PROCESS AND POWER PLANT COMPONENTS

In general during transport and erection, preservation measures of components are necessary. Furthermore, delays in construction or commissioning of nuclear power plants, combined cycle power plants, solar thermal power plants, refineries or other fabrication facilities leads to an increased risk for sensitive components due to corrosion or contamination. Therefore, it is important to preserve and store the sensitive and expensive components with adequate measures. Read more:

PROJECT ASSESSMENT AND RISK EVALUATION OF GRATE FIRED BOILERS FOR BIOMASS, WASTE AND RDS

An increased demand for the erection of grate fired boilers for biomass, waste and residual derived fuels (RDS) can be observed worldwide. In addition, the plant sizes continuously increase. Since the composition and quality of the fuels become more complex, the technical assessment and risk evaluation of such projects are key for future safe operation. The Allianz Center for Technology (AZT) provides a powerful tool for the assessment of grate fired boilers using complex fuels. Read more:

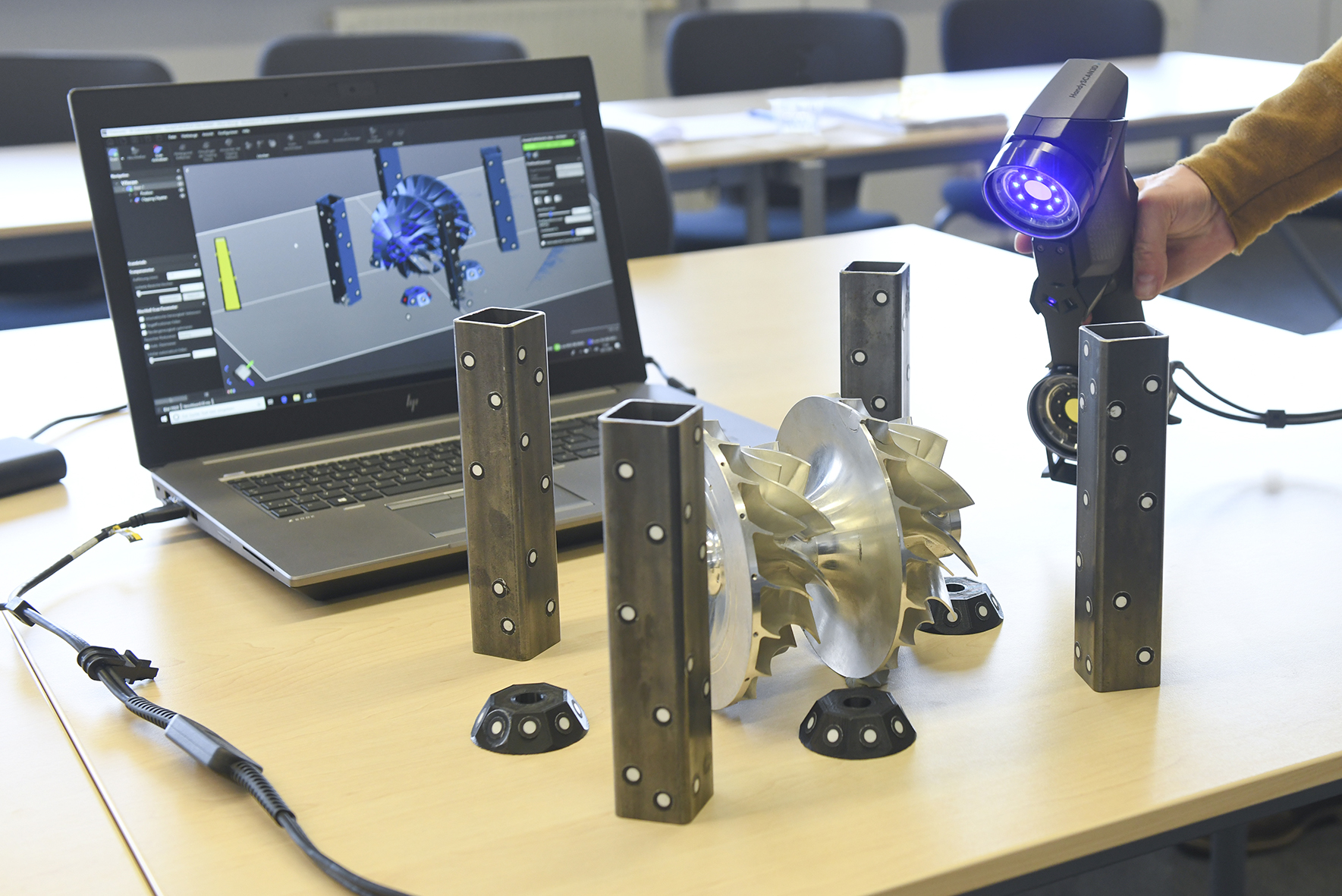

REMOTE LAB ACCESS (RLA)

AZT has developed the “Remote Lab Access (RLA)” service to provide a common live view on laboratory works by means of state of the art communication tools. RLA allows in the course of a root cause analysis for all parties involved to join and witness the lab investigations. Read more: