Topics at the Allianz Center for Technology:

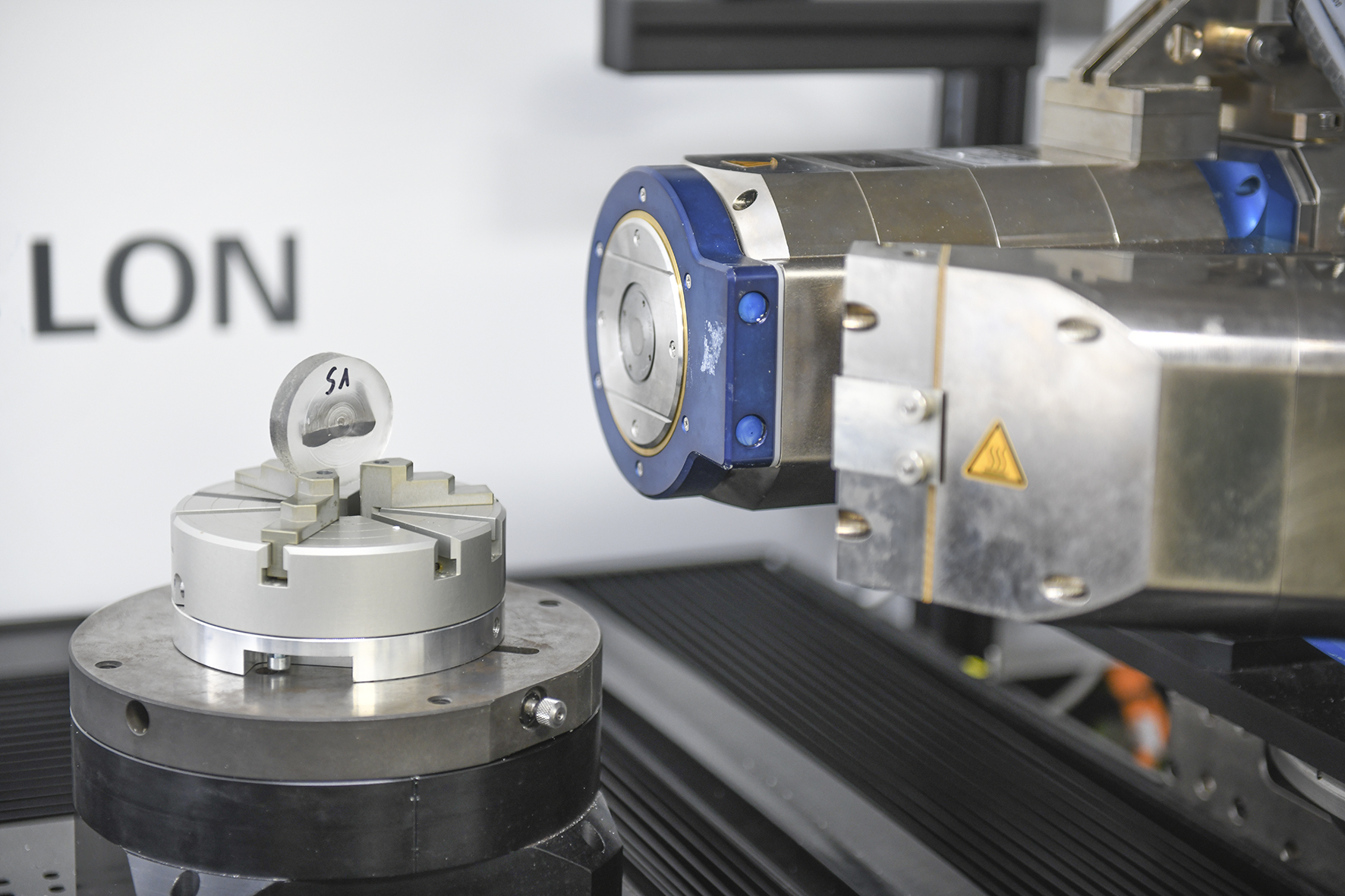

Computer Tomography (CT)

Ongoing developments and innovations are continuously changing non-destructive testing (NDT). Established techniques will be optimized and improved, new and innovative techniques are added to the NDT toolbox. In cooperation with our accredited partner laboratory, AZT is able to perform high-resolution CT scans of parts with various geometries and made from various materials. The inner structures of the examined objects can be illustrated in 3D.

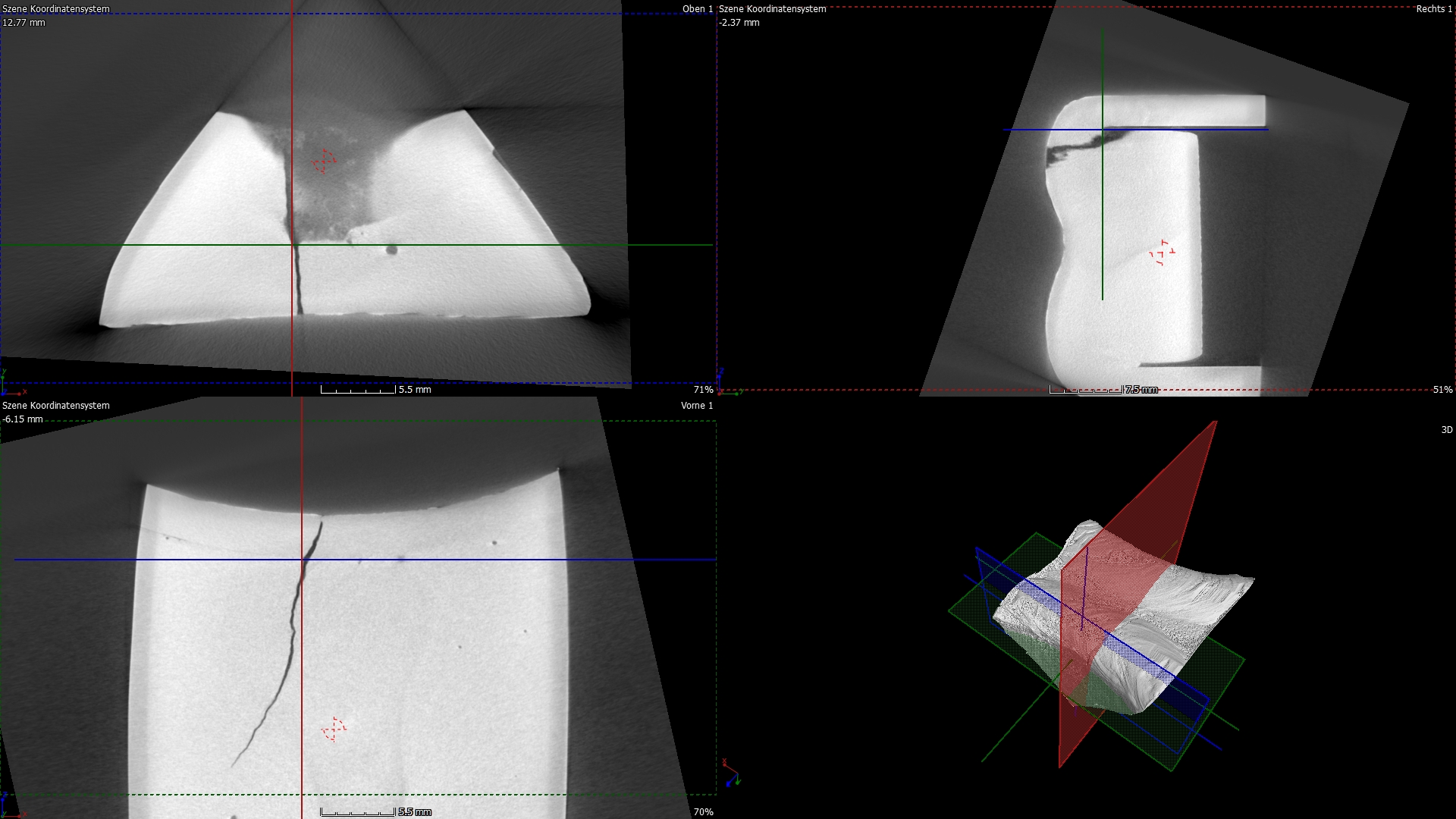

When performing failure analysis, CT examinations provides valuable information about location, orientation and geometry of the concerning imperfection. This often leads to first indications of the failure cause or mechanism. Knowing the exact location of the failure enables exact preparation of the concerning object to efficiently prepare further examination.

Furthermore, CT is a formidable tool for quality assurance. CT allows 3-dimensional non-destructive examinations of the inner structure of a wider range of products. Therefore, especially for new, innovative production techniques like additive manufacturing (3D- printing), CT is a valuable tool for process parameter validation and ongoing inspections during manufacturing.